TESTING AND INSPECTION

PHOENIX X-RAY PCBA|INSPECTOR 100 X-RAY MACHINE

|

|

|

MIRTEC MV-2HT DESKTOP AOI

|

VISION ENGINEERING MANTIS ELITE STEREO INSPECTION MAGNIFIER

|

|

ADDITIONAL TESTING AND INSPECTION EQUIPMENT

|

|

QUALITY ASSURANCE

Quality begins from the moment we quote your work to the final shipment. We can also provide a variety of testing and engineering support as required by our customers. All work is inspected to meet your specifications.

NO JOB IS TOO BIG OR TOO SMALL!

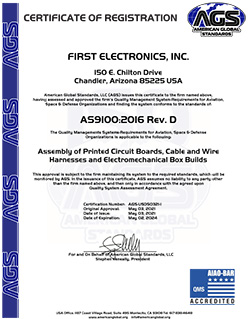

First Electronics, Inc. is an ISO 9001:2008 Certified Company. Along with our automated assembly we conform to ANSI/IPC-610 and Mil-STD-2000 certified workmanship standards. We also can comply with any UL requirements.